Sapphit™ for clean processes

Sapphit tubes for clean processes

Sapphire tubes and capillaries are the material of choice for manipulation with plasma, gas and liquids in applications where extremely high chemical purity and particulate cleanliness is required, e.g. semiconductor processing or ultra-high precision analytical methods.

- Chemical purity 99,995%

- High resistance against plasma corrosion

- High resistance against aggresive chemicals (even fluorinated compounds)

- High resistance against high temperatures (up to 2000°C)

- High RF transmission

Sapphire tubes in clean processes undergo a special surface treatment furhter lowering any surface contaminants on tube surfaces.

Benefits of hight purity material

Sapphire single crystal is replacing quartz glass and high quality ceramic (e.g. polycrystalline alumina) because it provides higher chemical purity and higher corrosion resistance which leads to reduction of risks of chemical or particulate contamination of the manufacturing process or tested specimens.

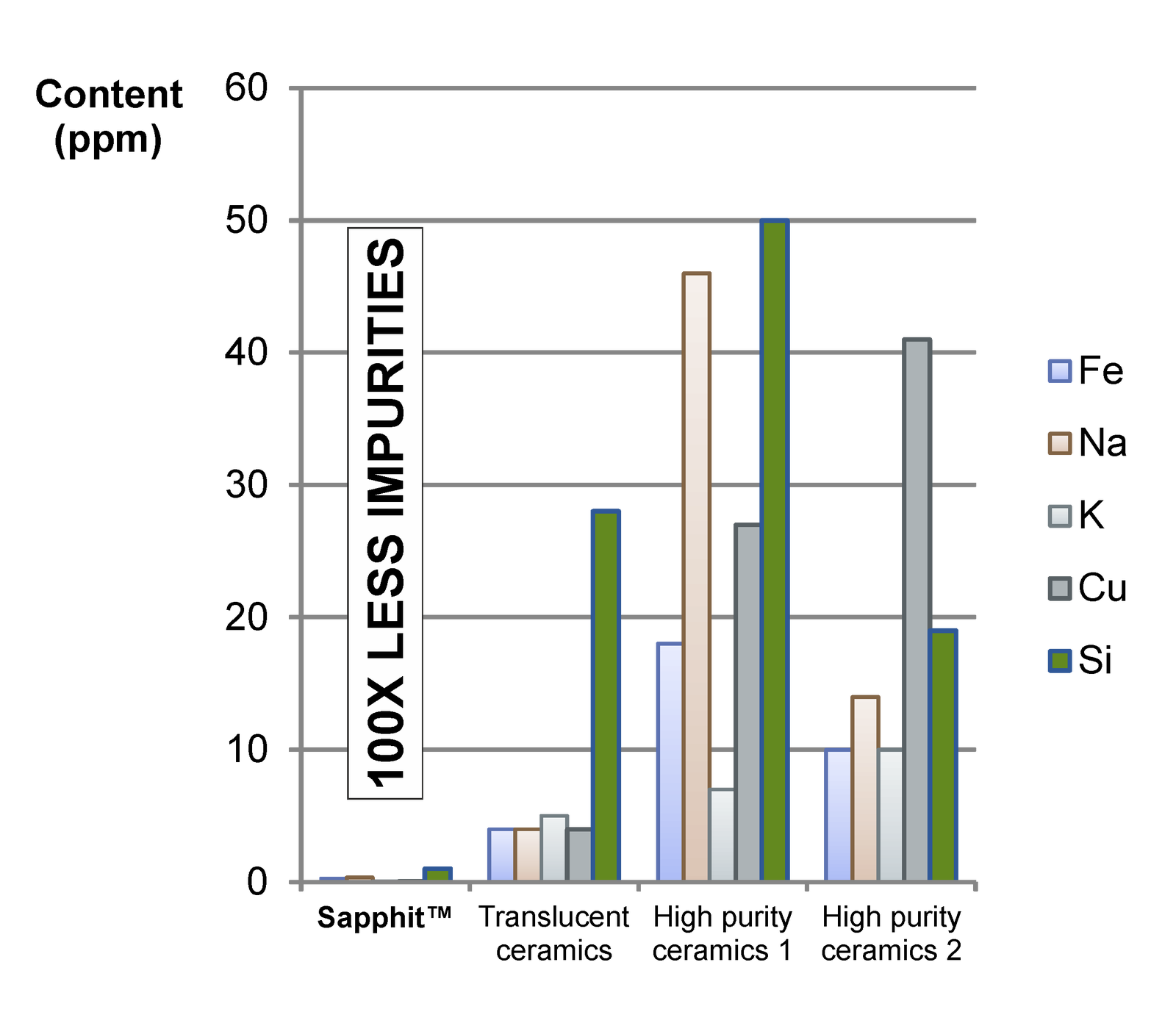

Comparison based on material analyses of Sapphit™ sapphire tubes and composition data by different manufacturers of sintered ceramics. High purity of Sapphit™ sapphire tubes cannot be matched even by high purity translucent ceramic, which indicates 100x more impurities in chemical analyses.

Clean-room packaging

Ultra-clean sapphire components can be handled and packed in clean-room environment to avoid any contamination during manipulation.

Examples of application in SEMI:

- plasma containment tubes and injectors

- plasma cleaning of surfaces

- chemical vapor deposition process (CVD)

- plasma (dry) etching

- plasma ashing

- wet etching

- thermocouple protection sheaths

Examples of application in analytical methods:

- plasma torches and injectors for ICP-MS or ICP-OES